Modern sock manufacturers face a critical decision. They ask if an automatic socks printing machine is a worthwhile investment. This technology offers many benefits. It also presents challenges. Businesses must carefully weigh these factors. They decide the best path forward for their production.

Key Takeaways

- Automatic sock printing machines make many socks fast. They help factories produce more socks quickly.

- These machines print socks with good quality. They make colors bright and designs clear every time.

- Automatic machines cost a lot at first. But they save money later by using less labor and materials.

The Advantages of Automatic Socks Printing Machines

Boosting Production Efficiency and Speed

Automatic socks printing machines significantly increase how many socks a factory can make. These machines work much faster than people. They can run for long periods without stopping. This means manufacturers produce more socks in less time. A single socks printing machine can produce many pairs quickly. This speed helps businesses meet large orders and customer demands. Factories become more productive overall.

Achieving Consistent Quality and Vibrant Colors

Machines follow precise instructions. This ensures every sock looks exactly the same. The colors printed are bright and true to the original design. Manual printing can sometimes have small errors or color differences. Automatic machines reduce these mistakes. They deliver uniform quality across all products. Customers receive socks with consistent patterns and vibrant colors every time.

Long-Term Cost Savings and Material Optimization

While the initial cost is high, automatic machines save money over time. They reduce the need for many workers to do repetitive tasks. This lowers labor costs for the manufacturer. These machines also use ink and materials very efficiently. They create less waste. Less waste means less money spent on materials. These savings add up, making the investment worthwhile in the long run.

Unlocking Design Flexibility and Customization

Automatic socks printing machines allow for complex and detailed designs. They can handle many colors at once. Designers can create unique patterns and intricate artwork. This technology makes it easier to offer custom socks. Businesses can quickly change designs to match new trends. This flexibility helps manufacturers offer a wider range of products. It also allows for more personalized options for customers.

Enhancing Workplace Safety and Employee Focus

Machines take over tasks that are repetitive or might be dangerous for workers. This makes the workplace safer for employees. Workers can then focus on more skilled jobs. They might manage the machines, design new patterns, or check product quality. This shift improves job satisfaction. It also allows employees to use their skills in more valuable ways. Investing in an automatic socks printing machine can transform a business.

Technical Capabilities of Modern Socks Printing Machines

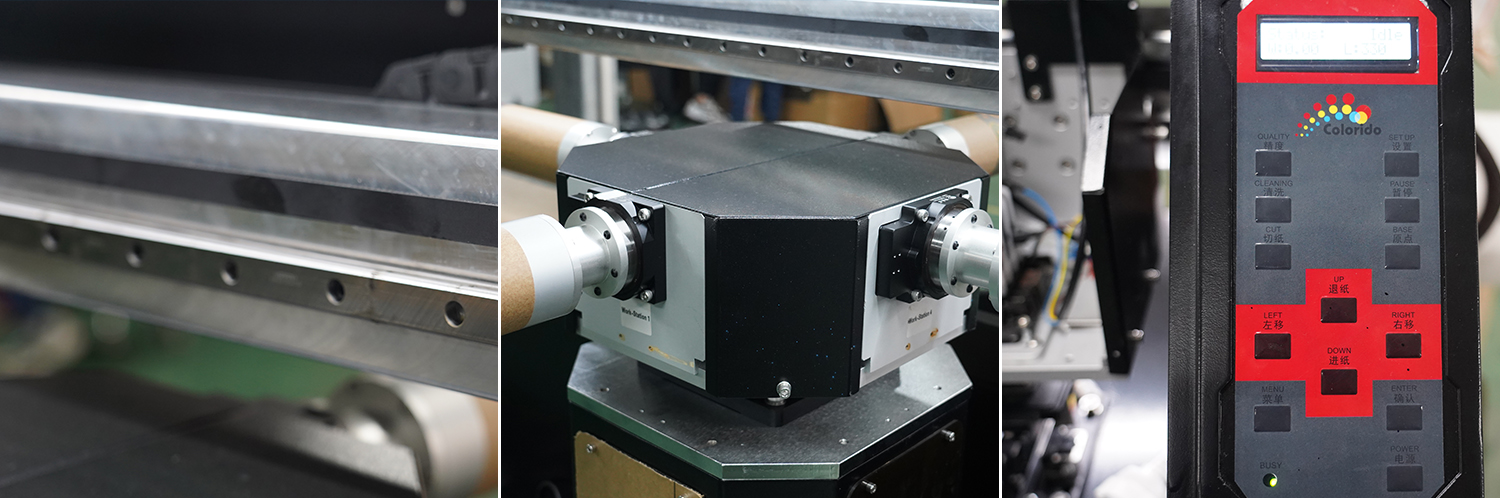

Advanced Printing Modes and Roller Systems

Modern socks printing machines use sophisticated technology. They feature advanced printing modes. These modes allow for different ink applications. Roller systems precisely guide each sock through the machine. These rollers ensure smooth movement. They also maintain correct sock tension. This setup guarantees even ink distribution. It prevents smudges or misalignments. Manufacturers achieve high-quality prints consistently.

Versatility Across Various Fabric Materials

These machines show great versatility. They print on many different fabric types. This includes cotton, polyester, nylon, and wool blends. The technology adapts to various material textures and thicknesses. This means manufacturers can produce a wide range of sock products. They do not need different machines for different fabrics. This capability expands product offerings significantly.

Precision Control for Intricate Designs

Modern machines offer exceptional precision. Advanced software controls the printing process. It places ink droplets with extreme accuracy. This allows for very intricate designs. Fine lines, small details, and complex patterns appear sharp. The colors align perfectly. This precision ensures every design looks exactly as intended.

The Power of 360-Degree Printing

A key feature is 360-degree printing. This technology prints designs seamlessly around the entire sock. It eliminates visible seams or blank areas. The design wraps continuously from one side to the other. This creates a more professional and appealing product. A socks printing machine with this capability offers superior aesthetic quality.

The Challenges of Adopting Automatic Socks Printing MachinesSignificant Initial Investment Considerations

Buying an automatic socks printing machine requires a large amount of money. Manufacturers must pay for the machine itself. They also need funds for installation. New software often comes with the machine. Workers need training to operate it. Factories might need upgrades to their power or space. These initial costs can be a major barrier. Smaller businesses often find this investment difficult. They may not have enough capital readily available.

Maintenance Needs and Technical Expertise

These complex machines need regular care. They require routine maintenance to run smoothly. Parts can wear out or break. Manufacturers need skilled technicians to fix these issues. Finding such experts can be challenging. Training existing staff takes time and money. Spare parts can also be expensive. Machine downtime during repairs means lost production. This affects a factory’s output and profits.

Limitations for Small Batch and Highly Customized Runs

Automatic systems work best for making many identical items. They are efficient for mass production. Setting up a new design takes time and effort. This setup process becomes costly for small orders. Highly customized runs, like a few unique pairs, are less efficient. Manual printing might be better for these specific jobs. The flexibility of human hands can quickly adapt to unique requests. Automatic machines struggle with frequent design changes for small quantities.

Addressing Potential Job Displacement

Machines can do tasks once done by people. This means some jobs may disappear. Automation can reduce the need for manual labor in certain areas. This change can affect workers and their families. Companies must consider the social impact. They can retrain employees for new roles. Workers might learn to manage machines or design new products. This helps them adapt to the changing workplace.

Mitigating Dependency on Technology and System Glitches

Factories rely heavily on these machines. If the technology fails, production stops. Software bugs can cause errors. Hardware malfunctions lead to breakdowns. Power outages can halt operations. This dependency means businesses need strong backup plans. They also need reliable IT support. A single glitch can disrupt the entire production line. This can lead to missed deadlines and unhappy customers.

Understanding Response Time for Automatic Socks Printing Machines

Setting up a new design on an automatic socks printing machine takes time. Engineers must load the design files. They need to adjust machine settings. They also perform test prints. While the actual printing is fast, this initial setup can be slow. Manual processes sometimes offer quicker adjustments for minor changes. Manufacturers must factor in this setup time. It impacts how quickly they can respond to new trends or urgent orders.

Strategic Implementation: Making Automation Work for YouAssessing Your Specific Production Requirements

Manufacturers must first evaluate their current production needs. They consider their daily sock output. They also look at the complexity of their designs. A clear budget helps guide their decisions. This assessment determines if automation truly fits their business model. It ensures the investment aligns with their specific goals.

Exploring Hybrid Automation Approaches

Some companies combine machine and human work. They use automatic machines for large, standard orders. Workers handle unique, small batches. This approach offers great flexibility. It balances efficiency with customization needs. This strategy allows businesses to serve diverse customer demands effectively.

Scalability and Future Growth Planning

Businesses should choose systems that can expand. They plan for increased production volume. They also consider new product types. This foresight ensures the investment supports long-term company growth. It helps them stay competitive in the evolving market. Planning for future needs makes automation a sustainable solution.

Manufacturers evaluate business goals, production volume, and budget. This guides their decision on an automatic socks printing machine. Automation offers efficiency, quality, and design flexibility. Yet, it presents challenges like initial cost and technical demands. Strategic planning and a phased approach integrate these advanced technologies. Embracing automation wisely ensures competitiveness and innovation.

FAQHow much does an automatic socks printing machine cost?

Automatic socks printing machines require a significant initial investment. The exact cost varies based on features and capabilities. Manufacturers also consider installation and training expenses.

Can these machines print on all types of sock materials?

Yes, modern machines offer great versatility. They print on various fabrics. This includes cotton, polyester, nylon, and wool blends. The technology adapts to different material textures.

Do automatic machines replace human workers?

Automation can reduce the need for some manual tasks. However, it often shifts employee roles. Workers can manage machines, design products, or perform quality checks. This creates new opportunities.

Media Contact

Company Name: Ningbo Haishu Colorido Digital Technology Co., Ltd.

Email: Send Email

Phone: +86 13967852601

Country: China

Website: https://www.coloridoprinting.com/